Speeding up the composting process for goat manure can help you preparfast decomposition of sheep manuree quality organic fertilizer quickly. Here are three tips to help you achieve that:

1. Optimize the Pile Size and Composition

Correct Pile Size: The size of your compost pile can significantly impact how quickly goat manure decomposes. A pile that’s too small won’t retain enough heat, while one that’s too large may not receive adequate aeration. Aim for a pile that’s about 3-5 feet in height and width to maintain the necessary heat and encourage microbial activity.

Balance Carbon-to-Nitrogen Ratio: Goat manure is high in nitrogen, so to speed up the composting process, it’s important to balance it with carbon-rich “brown” materials like dry leaves, straw, or wood chips. The ideal ratio is about 25-30 parts carbon to 1 part nitrogen. Achieving this balance can help prevent odors and create an environment that’s conducive to fast decomposition of sheep manure.

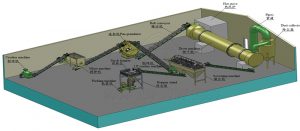

Manure compost products

2. Enhance Aeration and Turn Regularly

Regular Turning: Turning the compost pile regularly (every couple of days to once a week) can significantly speed up the process. Turning introduces oxygen into the pile, which is crucial for aerobic bacteria to thrive and break down the organic matter. Well-oxygenated compost piles will decompose much faster than those left unturned.

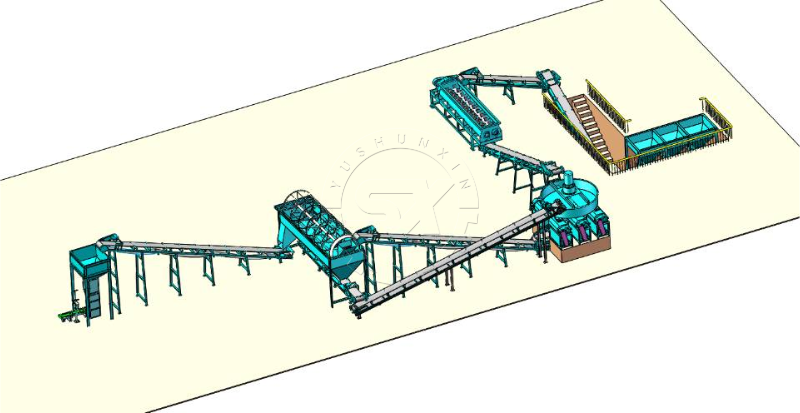

Use an professional goat manure compost machine: If manually turning the pile with a pitchfork or shovel seems too labor-intensive, consider using a professional compost turner of goat manure that you can push directly into the pile and turn compost piles to create air channels. This can be a less strenuous way to ensure your pile is well-aerated. Click here to learn more.

3. Maintain Proper Moisture and Temperature

Moisture Control: Microbes need moisture to survive, but too much water can create anaerobic conditions that slow down the composting process. Keep the compost as moist as a wrung-out sponge. During dry spells, you may need to add water, and during rainy periods, you may need to cover the pile to prevent it from getting too wet. In addition, we has dehydrator and water tank for goat poop compost making.

Monitor Temperature: The heat generated by microbial activity is a good indicator of the composting process. Piles that maintain a temperature between 130-160°F are composting effectively. You can use a compost thermometer to monitor the temperature and adjust your management practices accordingly. If the pile is too cool, you might need to turn it more often to reactivate the microorganisms.

Bonus Tip: Utilize Compost Accelerators

Add Compost Starters or Accelerators: Compost starters or accelerators contain beneficial microorganisms that can jumpstart the decomposition process. You can also add fresh green materials, such as vegetable scraps or grass clippings, which are high in nitrogen and can act as a natural accelerator.

By following these tips, you can speed up the composting of goat manure and enjoy the benefits of nutrient-rich organic fertilizer for your garden much sooner. Remember, though, while speed is desirable, ensuring a high-quality finished compost is the ultimate goal. If you want to make goat manure compost better, you can visit https://organicfertilizerproductionline.com/how-to-compost-goat-manure/