In the realm of agriculture and gardening, the importance of organic fertilizers cannot be overstated. They provide essential nutrients to the soil, improve its structure, and promote healthy plant growth. Horse manure is one such organic material that is highly beneficial for enriching the soil. However, utilizing horse manure efficiently and effectively requires proper processing and transformation. One of the most efficient methods to convert horse manure into valuable fertilizer is by using a horse manure disc pelletizer, especially when dealing with small capacities. In this article, we will explore the benefits and process of using a horse manure disc pelletizer to make fertilizer with small capacity.

Benefits of Using a Horse Manure Disc Pelletizer

- Efficient Conversion: A horse manure disc pelletizer is a specialized machine designed to transform raw horse manure into uniform-sized pellets. This process increases the surface area of the manure, allowing for faster decomposition and nutrient release. It ensures that the valuable nutrients present in horse manure are effectively utilized by plants, promoting healthy growth and higher yields.

- Nutrient Retention: Horse manure contains a wide range of essential nutrients such as nitrogen, phosphorus, and potassium, along with organic matter. However, these nutrients can be lost through leaching or volatilization if the manure is not properly processed. Using a disc pelletizer helps retain these nutrients within the pellets, minimizing nutrient loss and ensuring their availability to plants over an extended period.

- Enhanced Soil Structure: Pelletized horse manure acts as an excellent soil conditioner, improving its structure and overall fertility. The pellets enhance soil aeration and water retention, preventing compaction and water runoff. This leads to better root development, nutrient uptake, and overall plant health.

- Weed and Pathogen Control: The high temperatures reached during the pelletization process help in killing weed seeds and reducing the presence of harmful pathogens in the horse manure. This minimizes the risk of weed infestation and plant diseases, creating a healthier environment for your plants.

dic pelletizer for sale

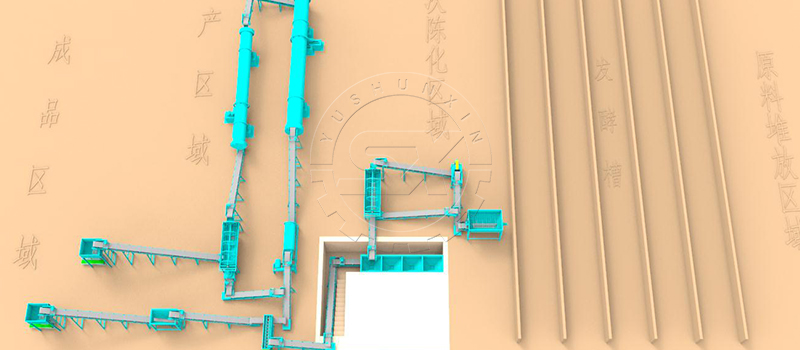

The Process of Using a Horse Manure Disc Pelletizer

- Raw Material Preparation: Before using the disc pelletizer, it is essential to properly prepare the horse manure. Remove any large debris or bedding materials, such as straw or wood shavings, from the manure to ensure a clean feedstock. You can also mix the horse manure with other organic materials like kitchen scraps or crop residues to enhance the nutrient content of the final fertilizer.

- Drying: If the horse manure is too moist, it is advisable to dry it to reduce the moisture content. Excessive moisture can lead to difficulties in pellet formation and result in low-quality pellets. Spread the manure in a thin layer and let it air dry naturally or use a mechanical drying method if necessary.

- Grinding and Mixing (Optional): If the horse manure contains larger chunks or fibrous materials, it is recommended to grind or shred it into smaller pieces. This will facilitate the pelletization process and ensure uniform pellet size. Additionally, you can mix the horse manure with other organic amendments like compost or agricultural lime to balance the nutrient composition.

- Pelletization: Once the horse manure is adequately prepared, it is ready for pelletization using the disc pelletizer. The machine consists of a rotating disc with adjustable angle and speed, which causes the raw material to form pellets as it passes through the disc. The size of the pellets can be controlled by adjusting the disc inclination, while the speed determines the production capacity.

- Drying and Cooling: After the pelletization process, the horse manure pellets need to be dried and cooled to reduce moisture content and ensure long-term storage stability. This can be achieved through natural air drying or using a specialized drying equipment. It is important to cool the pellets to room temperature before packaging or storage.

Conclusion

Utilizing horse manure as a valuable fertilizer resource can significantly benefit your gardening or farming endeavors. By using a horse manure disc pelletizer, you can efficiently convert raw horse manure into uniform pellets, retaining its nutrients and enhancing soil fertility. The process outlined above provides a step-by-step guide for making fertilizer with small capacity. Embracing this sustainable approach not only improves the health of your plants but also contributes to a greener and more environmentally friendly agricultural system. So, harness the power of horse manure and maximize its potential with a horse manure disc pelletizer!