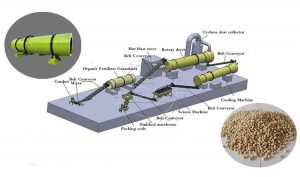

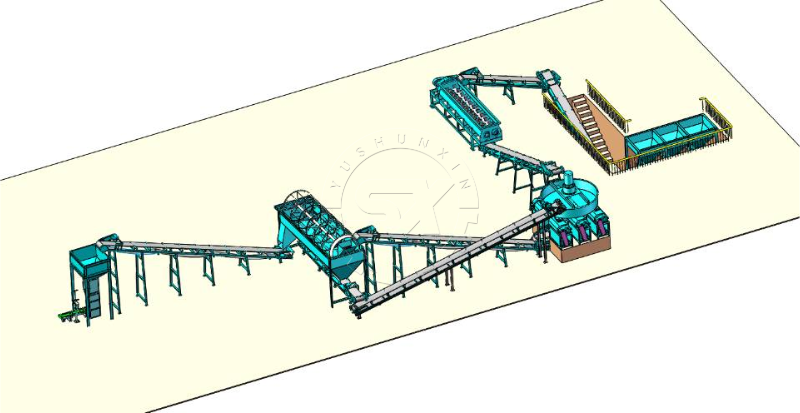

In the competitive world of fertilizer production, efficiency and cost-effectiveness are paramount. As the demand for high-quality fertilizers continues to rise, producers are constantly seeking ways to optimize their processes while minimizing costs. One of the most effective solutions to achieve these goals is the use of disc granulators in large-scale fertilizer production facilities. Disc granulators, also known as pan granulators, offer several economic benefits that can significantly enhance the profitability and sustainability of fertilizer manufacturing.

Cost Efficiency and Resource Optimization

One of the primary economic advantages of using disc granulators is their ability to optimize resource utilization. These machines are designed to convert raw materials into uniform granules efficiently, reducing waste and ensuring that the maximum possible volume of raw material is utilized. This not only cuts down on material costs but also enhances the yield of the production process. The precise control over granule size and consistency provided by disc granulators translates to less material being discarded or reprocessed, which can reduce the cost of large-scale fertilizer making operations.

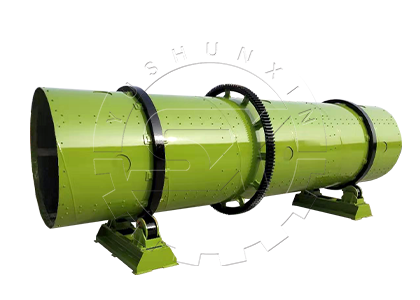

Energy Savings

Disc granulators are known for their energy-efficient operation. Compared to other granulation methods, such as drum granulation, disc granulation equipment require less energy to produce granules of the desired quality and size. The design of disc granulators allows for lower power consumption without compromising the quality of the output. In large-scale facilities, where energy costs can be a substantial part of the operational budget, this efficiency leads to considerable savings over time. Reduced energy consumption also aligns with sustainability goals, which can be an added economic benefit if facilities are pursuing green certifications or incentives. Learn more.

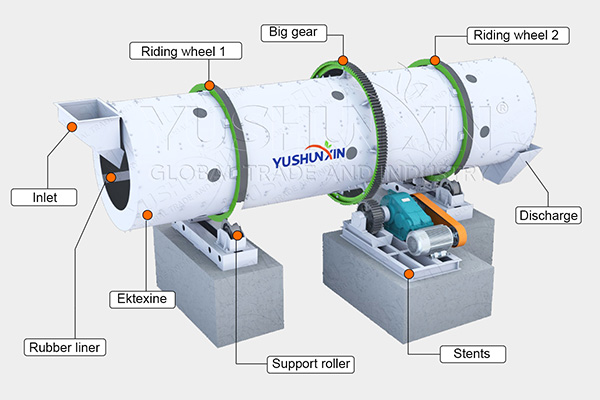

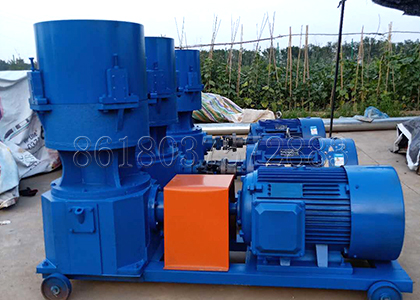

Reduced Maintenance Costs

The simple and robust carbon steel design of disc granulators contributes to their reliability and ease of maintenance. With fewer moving parts and straightforward operation, these machines experience less wear and tear, translating to lower maintenance costs. Regular maintenance routines are less intensive and less frequent, minimizing downtime and maximizing productivity. The longevity and durability of disc granulators mean that the initial investment yields long-term economic benefits, as replacement and repair costs are kept to a minimum.

Enhanced Product Quality and Marketability

Producing high-quality, uniform fertilizer granules is critical for marketability and customer satisfaction. Disc granulators produce fertilizer granules that meet the stringent quality standards demanded by agricultural markets. Consistent granule size and composition result in better nutrient distribution when applied, enhancing the effectiveness of the fertilizer. This quality assurance can command higher prices in the market, further bolstering the economic advantages for producers.

In conclusion, the integration of disc granulators into large-scale fertilizer production facilities offers numerous economic benefits. From optimizing resource use and reducing energy consumption to minimizing maintenance costs and enhancing product quality, these machines provide a cost-effective solution that can significantly impact the bottom line. As the agricultural industry continues to evolve, leveraging the advantages of disc granulators will be crucial for producers aiming to remain competitive and profitable. If you need to machine, you can visit https://fertilizerequipmentmanufacturer.com/fertilizer-granulator-machine/disc-granulator-machine/

.jpg)