What Raw Materials Are Suitable for Mineral Fertilizer Production?

In mineral fertilizer production, raw materials play a crucial role in determining the quality and effectiveness of the final product. Common materials include phosphate rock, potash, and various micronutrient ores. Phosphate rock, rich in phosphorus, is essential for plant growth and root development. Potash, derived from potash ores, provides potassium, crucial for photosynthesis and water regulation in plants. Micronutrient ores, such as those containing zinc and manganese, address soil deficiencies and enhance crop yields. Each of these materials has specific needs and benefits tailored to different agricultural and industrial applications.

Macroelement Mineral Materials of Pan Granulator

Why Is Binder Important in the Disc Granulation Process?

The binder in the disc granulation process serves a multifaceted role. Primarily, it acts as an adhesive, binding the fine mineral particles into larger, uniform granules. This not only improves the handling and application efficiency but also enhances the nutrient release profile of the fertilizer. A suitable binder ensures the granules remain intact during storage and transportation, reducing dust formation and nutrient loss. Therefore, selecting an appropriate binder is crucial for optimizing the production of high-quality mineral fertilizer granules.

How Does Granule Size Affect Fertilizer Application?

Granule size significantly impacts the application and effectiveness of mineral fertilizers. Larger granules tend to distribute nutrients more slowly, making them ideal for long-term soil conditioning. Conversely, smaller granules release nutrients more quickly, suitable for immediate plant uptake. The disc granulation machine allows for precise control over granule size, ensuring the fertilizer meets specific agronomic requirements. Consistent granule size also facilitates even spreading during application, promoting uniform crop growth and maximizing yield.

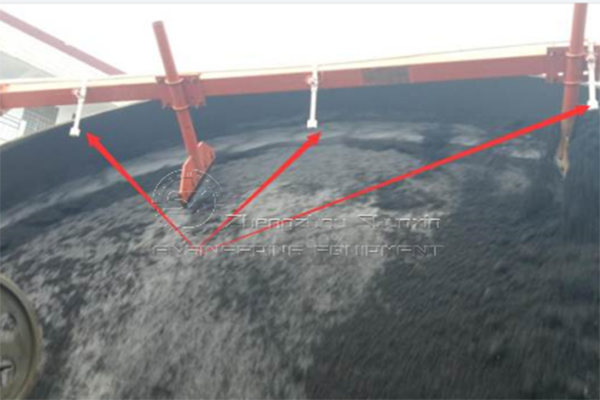

Disc granulator

What Machine Features Enhance the Disc Granulation Process?

Advanced machinery features are essential for optimizing the pan granulation process. Adjustable disc angles and rotational speeds allow for precise control over granule size and shape. Integrated moisture control systems ensure optimal binding and granule formation. High-quality materials and coatings on machine components reduce wear and extend equipment lifespan. These features collectively enhance the efficiency and reliability of the granulation process, ensuring consistent production of high-quality mineral fertilizer granules.

Why Choose Professional Equipment from Yushunxin?

In the competitive field of mineral fertilizer production, equipment quality is paramount. Yushunxin, a professional fertilizer equipment manufacturer, offers advanced granulation machinery designed to meet the specific needs of the industry. Their machines incorporate cutting-edge technology for precise control and efficient processing of raw materials. Investing in Yushunxin equipment ensures reliable, high-quality granule production, contributing to the overall success and profitability of fertilizer manufacturing operations.

Conclusion

In conclusion, the disc granulation process for mineral fertilizer production relies heavily on the appropriate selection of raw materials, the crucial role of binders, and the advanced features of granulation machinery. Each component plays a vital role in producing high-quality, effective fertilizer granules, ultimately benefiting various agricultural and industrial applications. You can visit: https://www.mineralfertilizerproductionsolutions.com/product/disc-granulator-machine/