Introduction

Zeolites are versatile and valuable materials used in various industrial applications, including water purification, gas separation, and catalysis. One common form of zeolite is granules, which are essential for many manufacturing processes. To produce high-quality zeolite granules efficiently, a pan pelletizer is a vital tool in the production line. In this guide, we will walk you through the steps on how to use a pan pelletizer to make zeolite granules effectively.

zeolite pellets

Understanding Zeolites

Before diving into the granulation process, it’s crucial to understand what zeolites are. Zeolites are crystalline aluminosilicate minerals known for their porous structure. They have a wide range of applications due to their ability to adsorb, exchange, and catalyze various molecules. To maximize the effectiveness of zeolite granules, it’s important to select the appropriate type of zeolite for your specific needs.

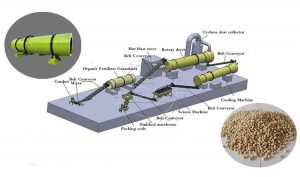

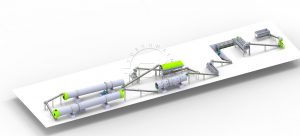

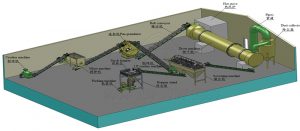

Choosing the Right Equipment

To produce zeolite granules, you’ll need a pan pelletizer. This equipment is specially designed to agglomerate fine powder materials into granules of uniform size and shape. Pan pelletizers come in various sizes and configurations, so choose one that suits your production requirements.

Preparing the Zeolite Powder

Start by obtaining zeolite powder. Ensure that the zeolite powder is of high purity and suitable for your intended application. It should also have the desired ion-exchange capacity, surface area, and pore size to meet your specific needs.

- Drying: If the zeolite powder contains moisture, it must be dried to eliminate any excess water content. Moisture can affect the granulation process and the quality of the resulting granules.rotary drum drying machine is necessary.

- Particle Size: Ensure that the zeolite powder is within the desired particle size range. The ideal particle size can vary depending on the specific application, but typically, a fine powder is used for granulation.

Granulation Process

Now that you have the necessary equipment and prepared zeolite powder, it’s time to begin the granulation process using the pan pelletizer.

- Loading the Pan: Place the zeolite powder into the pan pelletizer’s pan. The pan should be filled evenly to ensure uniform granule formation.

- Binder Addition: To facilitate granulation, you may need to add a binder solution. The binder helps hold the zeolite particles together during the granulation process. The choice of binder and its concentration should be carefully selected based on the characteristics of the zeolite and the desired granule properties.

- Mixing: Start the pan pelletizer and initiate the mixing process. The rotating pan will agitate the zeolite powder and binder solution, forming small granules.

- Granule Formation: As the mixing continues, the zeolite particles will gradually agglomerate into larger granules. Monitor the process to ensure the granules reach the desired size and consistency.

7.Drying: After granulation, the wet granules may need to be dried to remove any remaining moisture. The drying process should be carefully controlled to prevent overheating or damaging the zeolite granules.

Quality Control

- Sieve Analysis: Perform a sieve analysis to confirm that the zeolite granules meet the desired size distribution. Adjust the pan pelletizer settings as needed to achieve the desired granule size.

- Quality Testing: Conduct quality tests to ensure that the zeolite granules meet the required specifications for your application. This may include testing for ion-exchange capacity, surface area, and other relevant properties.

Conclusion

Using a pan pelletizer to make zeolite granules is a crucial step in the production of high-quality zeolite materials. By following these steps and carefully controlling the granulation process, you can produce zeolite granules that meet your specific needs and deliver exceptional performance in various industrial applications. Remember to select the right equipment, prepare your zeolite powder properly, and conduct quality control checks to ensure the success of your granulation process.