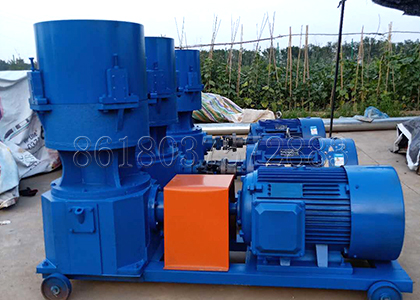

The bio organic pelleting machine is a great addition to any fertilizer production line. It will produce high-quality organic fertilizer out of many types of manure. The machine granulates the compost and turns it into pellets that can be sold or used to produce bigger and better crops. Read on to learn more about the bio pellet machine and how to use it in your business.

This machine has a rotating axle with multiple sharp teeth that help during the granulation process. This machine will produce large quantities of fertilizer pellets. If you want to make fertilizer quickly this machine can help you with your production process and help you make more money.

The machine fits in perfectly with any fertilizer production line. The machine makes the entire line faster and easier to use. The machine is efficient, affordable and it is easy to use. This granulator makes your pellets better and improves the quality of the pellets. It is important to have pellets that are high-quality so you can make the most money with them.

The granulating machine for bio organic fertilizer works by using the wet granulation method. This makes producing pellets faster since the materials don’t need to be dried out. They need to be fermented with the compost making machine and then they can be turned into pellets.

The raw materials go into the machine and then the rotor begins to work. The many teeth on the machine shred the materials and mix them so they begin to turn into granules. These granules will eventually turn into pellets. When the pellets are big enough they are ejected. The machine will produce lots of pellets. The machine doesn’t use a lot of energy and it is also eco-friendly which makes it a great choice for any fertilizer production operation.

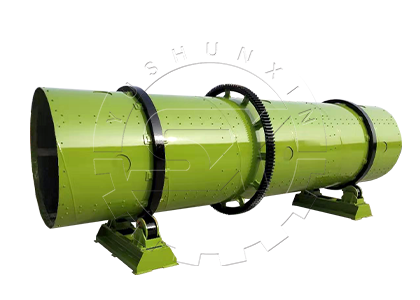

One of the big benefits of the machine is that the size of the pellets is adjustable. You can make pellets of almost any size by adjusting the rotating speed of the machine. The bio granules making machine yields better results than rotary drum granulators and disc granulators which makes it an affordable option that will help you get a lot of work done. The machine is easy to use and it has safety features that make using this powerful machine safe.

Bio organic fertilizers make the ideal fertilizer because they have bacteria that helps the plants. This fertilizer makes the plants grow better and it will help preserve nutrients. This fertilizer results in healthier crops and you also get a higher yield with your crops which makes this machine a quality investment for your business.

Bio organic fertilizers will help recondition the soil and they also have active soil microbes which makes the soil and crops healthier. The bio pellet machine is what you need to produce this fertilizer so you end up with a superior product. The crops will be happier and the soil will be better when you choose the bio pellet machine to produce all of your bio organic fertilizer.

When you have any purchase intention of the bio pellet mahcine, you can visit the following website or contact with us.

https://www.fertilizerfactorymachine.com/bio-pellet-machine/