Wet granulation is a widely used technique in the pharmaceutical, food processing, and chemical industries to create granules or pellets from fine powders. This process involves the mixing of a liquid binder with dry powders to form granules that are more easily handled, transported, and ultimately, processed. One of the key pieces of equipment employed in wet granulation process method is the granulator. In this article, we will delve into the fascinating world of granulators and explore how they use wet granulation to create pellets.

Understanding Granulation

Granulation is the process of transforming fine powder particles into larger, free-flowing, and more uniform granules. This is particularly important in industries where the handling and flow properties of materials are critical. Granules are easier to compress into tablets, fill into capsules, or mix with other ingredients. Additionally, granulation can improve the stability and content uniformity of pharmaceutical formulations.

The Role of Granulators

Granulators are essential machines in the wet granulation process. They play a pivotal role in mixing the powders and binder, as well as in shaping the resulting wet mass into granules. There are several types of granulators, each with its own set of advantages and limitations. However, all granulators used for wet granulation share some common principles.

Wet Granulation Process

Wet granulation typically follows a series of well-defined steps:

- Mixing: The first step involves blending the dry powders with a liquid binder. The binder can be water, ethanol, or other solvents, depending on the specific requirements of the process and the materials being used. This mixture forms a damp mass.

- Agitation: The damp mass is transferred to the granulator, which initiates the wetting and mixing process. The granulator uses various mechanical means, such as impellers, blades, or choppers, to promote even distribution of the binder throughout the powder.

- Nucleation: As the granulator continues to mix, small granules or nuclei begin to form. These nuclei serve as the foundation for the larger granules to develop.

- Growth: The nuclei grow in size as the granulator continues to agitate the mixture. The liquid binder acts as an adhesive, binding the powder particles together, forming granules.

Types of Granulators

There are several types of granulators used in wet granulation, including:

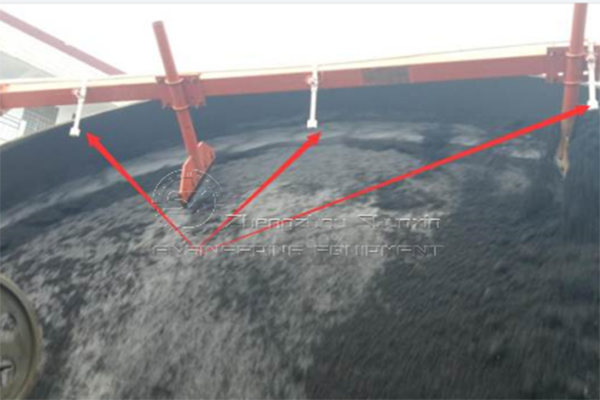

- Pan Granulators Equipment: It uses a disc and a scraper to rub against each other to produce particles. The equipment is also equipped with a water spray device. They are suitable for small production.

- Drum Granulators: These granulators work by tumbling the damp mass in a rotating drum pelletizer. The gentle tumbling action encourages the growth of granules.

disc pelletizer for pellets with water spray

rotary drum granulation machine

Benefits of Wet Granulation

Wet granulation offers several advantages over dry granulation or direct compression methods. Some of the benefits include:

- Improved Flow Properties: Granules have better flow properties than powders, making them easier to handle and process.

- Enhanced Content Uniformity: The uniform distribution of the binder ensures consistent drug content in pharmaceutical formulations.

- Better Compression Characteristics: Granules compress more uniformly and at lower pressures, making them ideal for tablet production.

- Increased Stability: Granules can protect sensitive ingredients from degradation during storage.

Conclusion

Granulators play a crucial role in the wet granulation process, transforming fine powders into uniform, free-flowing granules. Depending on the specific requirements of the industry and application, various types of granulators are employed to achieve the desired granule properties. Wet granulation offers several advantages, including improved flow properties, content uniformity, and stability. Understanding the intricacies of granulators and wet granulation is fundamental for industries that rely on high-quality granulated products.